ditax

engineering

We provide services of design office and production in the field of general mechanical engineering, production of equipment for the automation of the production process and in the field of plastic injection for the electrical and mechanical engineering industry.

Adaptation of the model components for the needs of the technological process of casting under pressure into the mold from the supplied CAD model or the delivered technical documentation for manufactured parts (mold release draft angles and shrinkage).

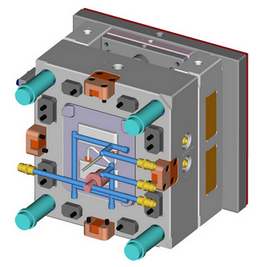

Addressing multiplicity of forms for economical use in the case of existing particular injection molding press.

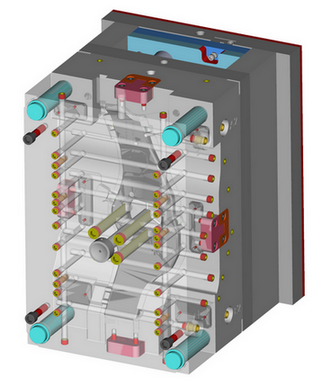

Optimized design of all functional details such as plungers, chillers, extractors, intake system, nozzles.

Provide the production and assembly of individual assemblies groups of designed injection mold according to detailed technical documentation.

We have a 3D printer available to verify the functionality of design and overall design, enabling us to create physical models of the designed solution up to 25 x 21 x 20 cm.

In this way, we can precisely fine-tune the details of the structure based on real feedback from the analysis on real objects, PCB mounting in housing with precise location of holes for connectors, sensors, LEDs and ventilation.

Printing is possible from PLA or ABS materials.

In the first step, based on the digital model provided by you as step format or at least the basic dimensions and your ideas, we design a proposal or more design alternatives.

You will get these from us as rendered outputs in graphical format. Based on your suggestions, we process or fine-tune the design of the enclosure until you are satisfied with the solution.

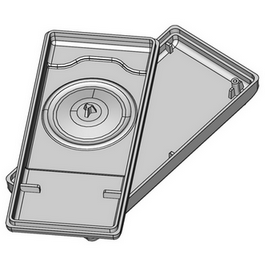

Subsequently, the individual parts of the enclosure are modeled according to the finished design. These include the necessary functional elements such as connector, sensors and indicators hole details, bearing elements for positioning and PCB mounting, and others.

The design of these parts is, of course, in relation to the injection molding technology used, i.e. the correct solution of the parting line, the necessary molding angles of walls and their optimum thickness, reinforcing elements, mounting elements, shape and dimensioning of the rim according to the desired method of closing and sealing. This model is printed on a 3D printer to verify functionality.

For too complicated parts, if required, due to the doubt of shape and dimensions choice of the critical geometric details of the given solution of enclosure, it is possible to provide an analysis of the injection molding process using the Moldflow program.

On the basis of the finished CAD model, the injection mold is designed and constructed. The solution of the structural and technological elements of the mold depends on the shape and the functional elements of the given enclosure solution, the required life of the mold and the cadence of the production, the texture of the appearance elements and the desired precision of the parts.

After production of the injection mold, sample parts are made, which are subjected to analyses to assess the desired quality. Outputs of these analyses are possible corrections and/or additional technological elements that are then incorporated into the mold. This step is repeated until the desired mold quality is achieved.

After agreeing on the production batch of your products, the mold is set up on injection machine, a process is fine-tuned, and the desired batch is made with the necessary quality control.

The parts are then assembled with the insertion of the printed circuit boards and their sealing and/or labeling. The closing of the sealing is done either mechanically by means of bonding materials or by gluing or ultrasonic welding, according to the solution proposed in the technological design phase of the parts.

After inspection, finished products are wrapped in packages, stacked in crates and sent to you.